Fiber Optic Temperature Test Applications

Fiber Optic Transceiver manufacturers test these devices to assure optical transceivers circuits work at certain temperatures. This is to guarantee reliability of these high speed fiber optic transceivers used within the communication high speed network and data center industries.

Temperature Cycling Optical Transceivers – Accelerated Life Testing – Fast temperature Cycling – Thermal Shock – 100G Optical Transceiver

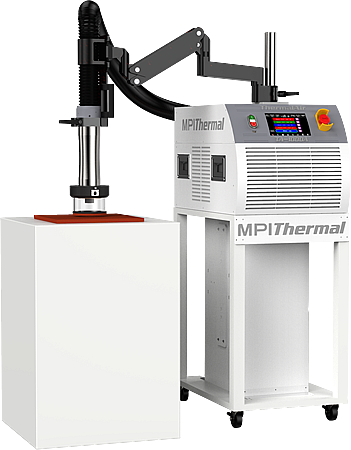

ThermalAir TA-Series of Temperature Forcing Systems

ThermalAir Temperature Test Systems are used for fiber optic manufacturing final test applications in engineering development and production at temperature ranges from -40°C to +90°C to thermal test and temperature calibrate these devices at precise temperatures.

ThermalAir TA-5000 -80°C to +225°C, TA-3000 -65C° to +225°C and TA-1000 -25°C to +200°C temperature inducing equipment provides a controlled temperature of hot and cold air directly on the fiber optic component under test with temperatures ranging from -80°C to +225°C with an accuracy of +/- 1.0°C for fiber optic components.

Fiber Optic Components

Commercial SFPs and other Fiber Optic components are designed to withstand temperatures between 0°C and 70°C. Some of RAD’s SFPs are industry hardened versions, designed and tested to operate from -40°C to +90°C at a temperature margin within the set point better than +/- 1.0°C. These and other families of Fiber Optic Transceivers specified temperature ranges may vary according to where the product in which the Fiber Optic Component SFP and others are used.

-

Industrially Hardened

-

DDM Calibration

-

External DDM Calibration

-

And More Advance specification requirements

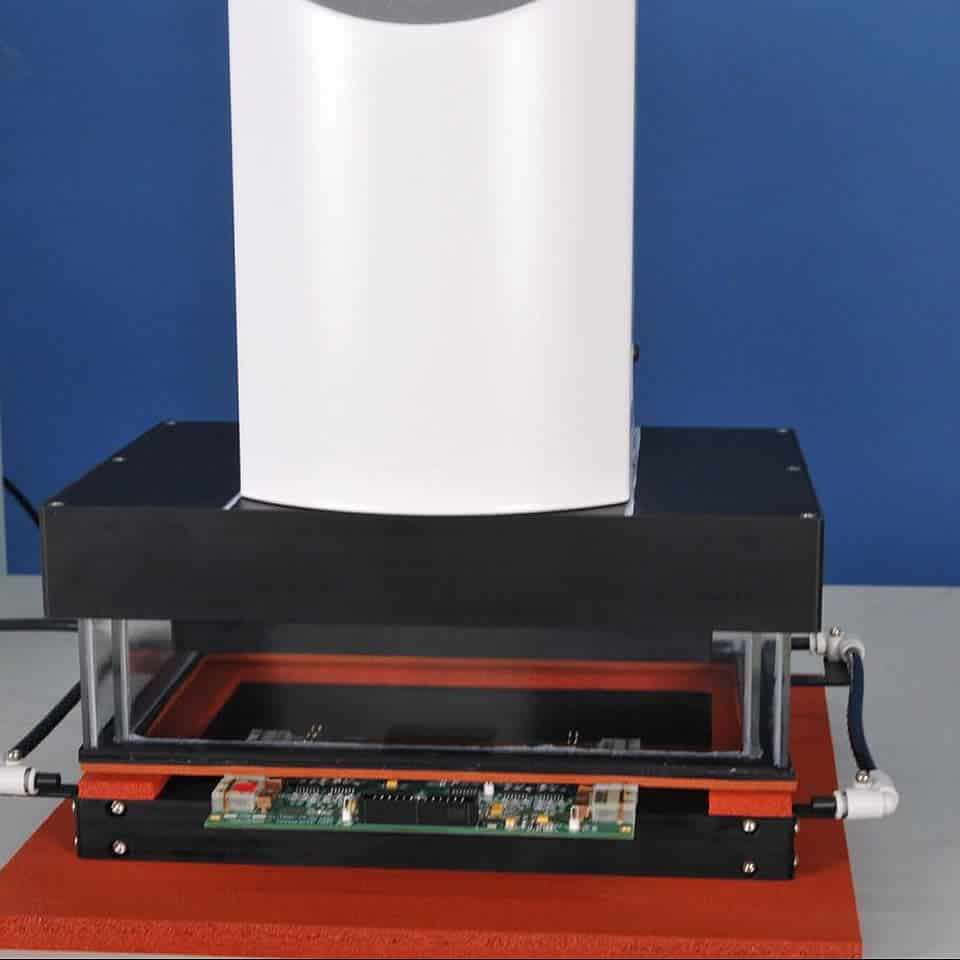

ThermalAir Systems for SFP Fiber Optic Transceiver

Thermal Test Applications

ThermalAir TA-5000 system controls temperature for testing microelectronic and other electronic and non-electronic materials. This assures your parts are suitable for use within industrial, commercial and consumer electronic systems. These include basic temperature tests to determine characteristics of these fiber optic transceivers / laser devices over temperature.

Testing 40G Optical Transceivers – Environmental Temperature Testing – Temperature Test Chambers – HALT/HASS – Temperature Cycling Optical Transceivers

Thermal Cycling Fiber Optic Components

Standard environmental test chambers cannot meet the narrow temperature accuracy margins for 25G, 40G, 100G and 400G fiber optic transceiver.

ThermalAir systems produce a hot and cold stream of air at very fast ramp rates directed on the device under test with very precise thermal control, providing a temperature range from -80°C to +225°C with an accuracy of +/- 1.0°C for fiber optic transceivers and other high speed electronic components.

MPI Thermal temperature inducing equipment is portable and can easily be moved from one test station to another. Fiber Optic Component manufacturers can use our ThermalAir TA-5000 system to quickly bring their parts to temperature right at the test location. Temperature cycling, thermal profiling and other environmental temperature conditioning is why MPI Thermal systems are part of the manufacturing temperature test processes.

Temperature cycling, thermal profiling and other environmental temperature conditioning is why MPI Thermal systems are part of the manufacturing temperature test process.

This is why the MPI Thermal TA-5000 Series of ThermalAir temperature products are part of the test.